Home » Vietnam News » Products » Tsubaki Solutions: Ensuring High Performance in the Noodle-Making Industry

Tsubaki Solutions: Ensuring High Performance in the Noodle-Making Industry

Discover how Tsubaki solves the challenges of noodle production. Learn about our heat-resistant chains, high-precision reducers, and other solutions that optimize performance, safety, and cost

In the noodle-making industry, every stage is a critical link that demands seamless coordination and absolute reliability from the power transmission system. The unique production environment, with its high temperatures, humidity, and strict food safety requirements, presents numerous challenges for manufacturers. Tsubaki, with its extensive experience and diverse product portfolio, offers specialized technical solutions to address these issues, ensuring continuous operation and maximum efficiency.

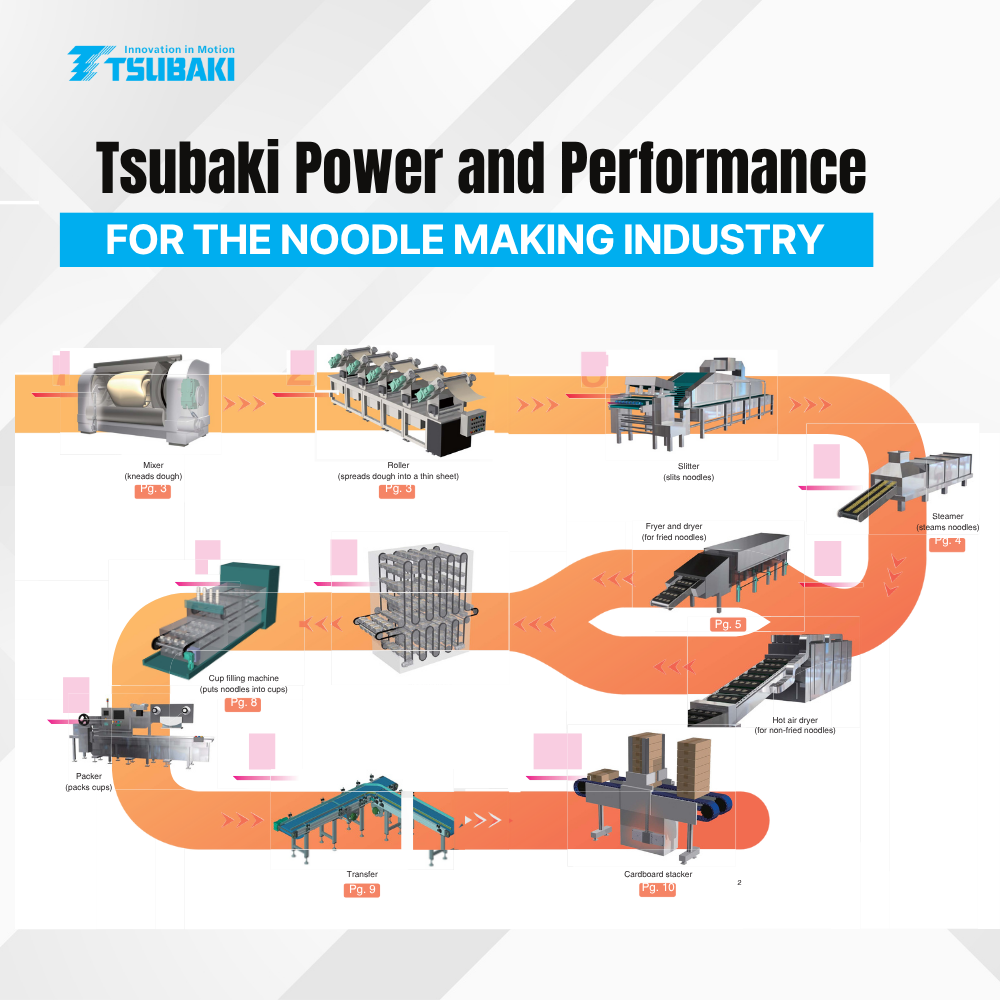

Optimal Solutions for Each Stage

Mixing & Rolling Stage

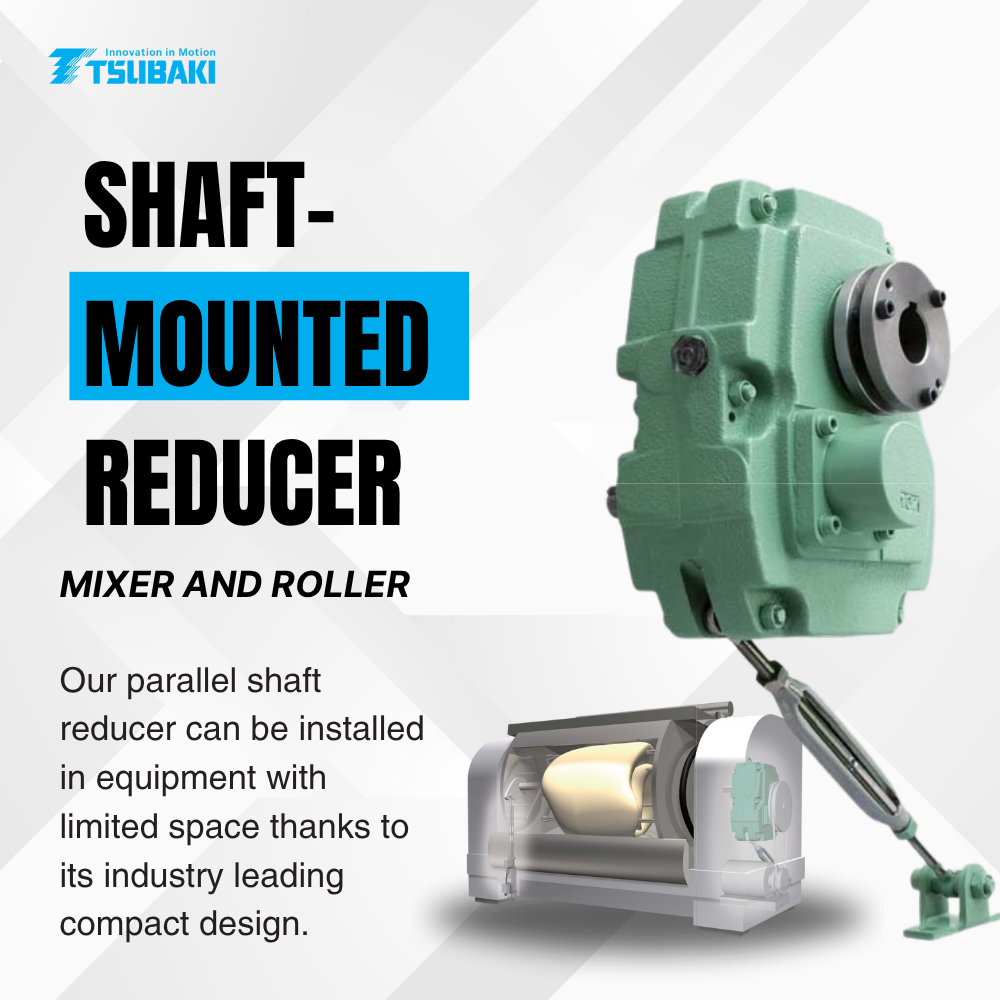

This stage determines the quality and elasticity of the noodles. Tsubaki provides a range of specialized reducers for mixers and rollers, including:

-

Hypoid Motors: The right-angle hollow shaft design saves installation space while achieving high transmission efficiency.

-

Croise Motors: These utilize worm gears to ensure quiet operation, high durability, and resistance to heavy loads.

-

Shaft-mounted Reducers: Compact and flexible, ideal for equipment with limited space.

Steaming & Drying Stage

This is the most demanding environment, with high temperatures and humidity. Standard conveyor chains are prone to wear and corrosion, leading to production downtime.

This stage determines the quality and elasticity of the noodles. Tsubaki provides a range of specialized reducers for mixers and rollers, including:

-

LSK Series and NS Series (SUS316) Chains: Made from stainless steel, these are specifically for high-temperature and corrosive environments. The NS Series in particular offers resistance to stress corrosion cracking.

-

Lambda Lube-Free Chains: These use special oil-impregnated bushings certified NSF-H1, ensuring food safety. They are the ideal solution for resisting high temperatures and corrosion from water-based cleaning processes.

-

Shock Monitor Load Monitoring Device: This helps detect minor load changes due to a lack of lubrication, providing an early warning for timely maintenance and reducing the risk of a breakdown.

Accumulating & Packaging Stage

Precision is a key factor at this stage. Tsubaki offers solutions that help position and dispense products accurately.

-

Bearing Bush and X-Lambda Chains: These are designed to meet the high-precision positioning needs of cup-filling machines.

-

MYDEX® Indexing Drive and TERVO Series Reducers: These ensure high accuracy and rigidity for cup-sealing applications.

Conveying Stage

To ensure products are moved continuously, safely, and hygienically:

-

Modular Plastic Chains: A flexible alternative to conveyor belts, they help reduce slippage and misalignment, while improving durability and ease of cleaning.

-

Reducers for the Food Industry: With an antibacterial coating and NSF-H1 certified grease, they contribute to food safety throughout the process.

Why Tsubaki is the Top Choice

Tsubaki's solutions are not just about providing products; they are a commitment to performance, reliability, and long-term economic efficiency. With products specifically designed for each production stage, Tsubaki helps businesses:

-

Increase System Lifespan: Reduce wear and corrosion in harsh environments, extending the operational life of machinery.

-

Optimize Productivity: Ensure high precision and minimize unplanned downtime, keeping the production line running continuously.

-

Cut Costs: Lower maintenance, repair, and replacement costs thanks to the durability and stability of the products.

-

Ensure Hygiene and Safety: Products are certified for food safety, meeting the industry's most stringent standards.