Home » Vietnam News » Products » Tsubaki Synchronous Belts: The Precise & Lube-Free Power Transmission Solution for the Industry 4.0 Era

Tsubaki Synchronous Belts: The Precise & Lube-Free Power Transmission Solution for the Industry 4.0 Era

In modern manufacturing, the demand for precise power transmissionhigh speed, and clean working environments (clean rooms) is becoming increasingly critical. Tsubaki Synchronous Belts (Tsubaki Toothed Belts) are the perfect answer, designed to eliminate slippage, reduce noise, and notably, require no lubrication. This article will delve into the unique features (USPs) that have established Tsubaki as a world leader in toothed belt supply.

How Tsubaki Synchronous Belts Work

The core difference between Synchronous Belts and friction belts (V-belts, Flat-belts) is the mechanism of positive engagement drive. The teeth on the Tsubaki belt engage precisely with the grooves on the belt sprocket, ensuring torque transmission is reliable, synchronized, and slippage-free.

With a robust composition of Chloroprene rubber, high-tensile glass/aramid fiber cords, and reinforced teeth, Tsubaki belts guarantee long-lasting performance.

3 Differentiating Factors That Define Tsubaki Synchronous Belts'Special Features

Based on proprietary technology, Tsubaki Belts boast three distinct competitive advantages:

1. Ultra-High Precision Thanks to Hybrid Core Technology

If precision is the top priority, Tsubaki has the solution:

-

Ultra PX Belt HY Type: This is Tsubaki's strongest product line, featuring a Hybrid Core (Carbon and Glass Fiber). This combination provides 1.3 to 2.0 times higher tensile strength and rigidity compared to standard lines. The result is near-absolute minimization of elongation under load, ensuring extremely accurate and stable positioning.

-

Just Touch System: The proprietary tooth design ensures optimal contact between the belt teeth and the pulley, reducing noise and enhancing engagement.

2. The Clean Drive Solution: Completely Lube-Free

This is a major advantage over traditional chain drive systems. Tsubaki synchronous belts do not require any lubrication:

-

Eliminates Contamination Risk: Ensures a clean working environment, ideal for sensitive industries like Food & Beverage, Pharmaceuticals, and Packaging.

-

PX Belt Shinayaka 530 Type: This specialized design helps minimize rubber debris generated from wear, keeping machinery and products pristine.

3. Built for Harsh Environmental Resistance

Not only powerful, Tsubaki belts are durable in challenging conditions:

-

Ultra PX Belt HA Type (Oil/Water Proof): Constructed with oil-resistant rubber, the HA Type maintains high transmission capacity even when frequently exposed to oil and water. This makes it the perfect choice for applications requiring regular washdowns or operating in humid environments.

-

Reduced Downtime: The material durability extends the belt's lifespan and reduces maintenance frequency, thereby maximizing the facility's uptime.

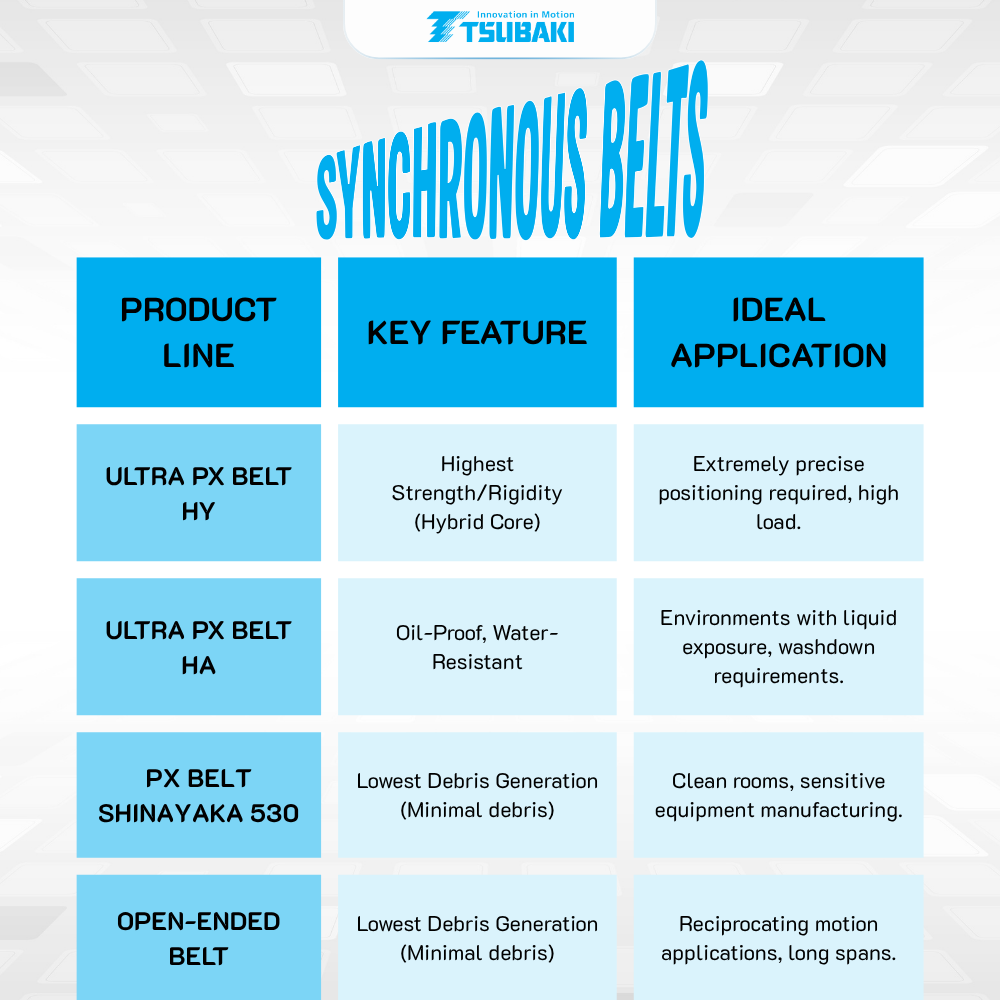

Overview of Tsubaki's Key Product Lines

Tsubaki Synchronous Belts are a strategic investment that helps your plant achieve maximum precision, durability, and efficiency. Eliminate the risk of slippage and the need for costly lubrication today!

-

Contact for Consultation: To have the Tsubaki Vietnam engineering team provide detailed advice on the best synchronous belt solution for your needs, please contact info@tsubaki.net.vn.

-

Meet Us in Person: Don't miss the chance to see the products live at Booth 792A, VIMF 2025 this November!

Tsubakimoto Vietnam - Innovation In Motion

🌐 Website: https://tsubaki.net.vn/

👉 Click for detail Synchronous Belt Catalog: https://tt-net.tsubakimoto.co.jp/tecs/pdct/tbl/pdct_tbl_1tblgb.asp